Eco Products

- Developing Environmentally Friendly Products

- Management of Chemical Substances

- Developing Environmentally Friendly Maintenance Products

Glory develops environmentally friendly products that minimize the environmental impact throughout the product life cycle, from material procurement and customer use to final disposal.

Developing Environmentally Friendly Products

Self-checkout change dispenser (RT/RAD-S1000)

The Glory Group is committed to developing environmentally friendly products as a part of our initiatives towards net-zero CO2 emission. In response to our customers' requests, we conduct Life Cycle Assessments (LCA) to examine the environmental impact at each stage of our product lifecycle, from material procurement, end customer use, to final disposal.

In product development, we conduct product assessment against existing products over 40 categories from energy efficiency to reuse-recycling. Ones that meet in-house standards are certified as G-Eco products (e.g., 15+% electric power use efficiency, compliant with chemical substance regulations, etc.).

Among the products developed in fiscal 2023, ‘RT/RAD-S1000’, self-checkout change dispenser launched for the retail and transportation market, is designed to reduce power consumption by 18% compared to our conventional models.

Management of Chemical Substances

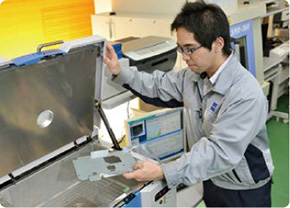

Inspecting parts for chemical substance content

Glory designates materials regulated by the RoHS Directive, REACH Regulation, and other laws and regulations in the Glory Specified Chemical Substances List. It also stipulates banned materials in the Green Procurement Standards to facilitate the thorough management of chemical substances contained in our products.

In addition to confirming compliance with regulations concerning chemical substance content during the parts selection process, we use X-ray fluorescence spectrometers to inspect all parts carefully as they are delivered. We also measure chemical content amounts, which are registered in the Chemical Substance Control System, making it easy to tally amounts for the overall product. Furthermore, all new products are inspected before shipping to comply with relevant regulations.

Supplier cooperation is essential for controlling chemical substances. We request that domestic and overseas suppliers ensure the parts and materials shipped to us fully comply with the Glory Green Procurement Standards. They are also asked to execute a memorandum of understanding on green procurement and provide data concerning chemical substance content.

Developing Environmentally Friendly Maintenance Products

Using a Recycle Jet for maintenance

Recycle Jet

Glory developed the Recycle Jet air duster as an environmentally friendly maintenance product that removes dust and other contaminants from electronics and precision machinery. Instead of typically used chlorofluorocarbon (CFC) alternatives, the Recycle Jet is filled with carbon dioxide (CO2) injection gas recovered as an industrial by-product yielding a global warming potential of just 1/1,430 of that of existing products, thereby helping to prevent global warming. Since carbon dioxide is non-flammable and therefore has no risk of igniting, the product is extremely safe. In addition, its reusable and detachable cylinder minimizes waste.

We have established our own recycling-oriented scheme that makes use of a nationwide network of more than 100 service locations, towards achieving a recyclingoriented society. Through this scheme, technical staff collect used cylinders during routine maintenance work and then send the cylinders to affiliated carbon dioxide filling facilities to be refilled with injection gas.

The number of filled cylinders in fiscal 2023 was about 38,996.