Eco Factories/Eco Offcies

- Addressing climate change

- Effective Use of Resources

- Water efficiency

- Management and Reduction of Chemical Substances

The Glory Group has been working to preserve the environment through initiatives to reduce environmental impact of its business activities. Through these initiatives, we support the reduction of CO2 emissions, appropriate management of chemical substances, and an efficient use of available resources.

Addressing climate change

Glory’s Environmental Policies covers the mitigation of global warming. We regularly monitor our greenhouse gas emissions and work to reduce those emissions from all of our supply chains.

In support of the long-term goals agreed upon in the United Nations Framework Convention on Climate Change (Paris Agreement) that promotes the reduction of greenhouse gas emissions by 2050, we have set our own long-term environmental sustainability goals to reduce CO2 emissions and to address climate change.

Efficient Use of Resources

Glory promotes the 3Rs (Reduce, Reuse, Recycle) to support the further development of recycling-based society.

For resource efficiency, we are constantly working to improve our production processes. This includes raising parts manufacturing yields and reducing the number of manufacturing trials to cut down on the volume of materials used.

Our factories and offices are going paperless, while we promote the use of returnable containers for deliveries from suppliers, and the reuse of cushioning materials for parts shipping within the Group.

We ensure that wastes are properly sorted before being disposed for recycling. As a part of our zero emission initiatives, we are currently working to achieve a recycling rate of 99.5% at all our production sites.

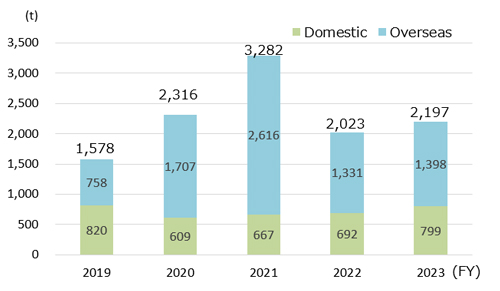

Waste Volume

*ISO14001 certified sites (Glory and its domestic and overseas consolidated subsidiaries)

*An increase in FY2020 was subject to the changes made to our product disposal procedures and the launch of new factory in our overseas production site.

Water efficiency

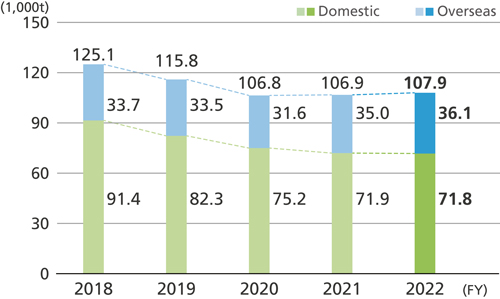

Water Usage

*ISO14001 certified sites (Glory and its domestic and overseas consolidated subsidiaries)

Management and Reduction of Chemical Substances

We carefully manage the chemical substances used in production, and are gradually switching our production materials to the ones with a low impact on human health. The factories manage and issue semi-annual reports on the amount of chemical substances used. We provide the required training to the factory employees who handle chemical substances, including those subject to the Law concerning Pollutant Release and Transfer Register (PRTR Law). Employees carry Safety Data Sheets (SDS) containing the information on chemical substance safety, so that they can be aware of precautions and emergency procedures.

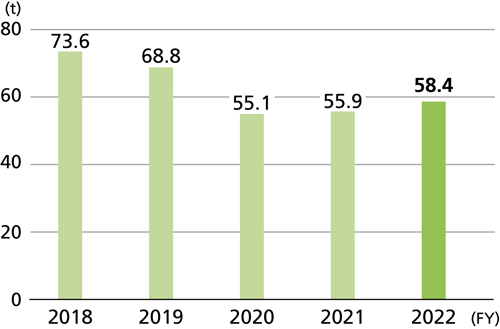

Volume of PRTR Law-Listed Substances (Domestic)

*ISO14001 certified sites (Glory and its domestic consolidated subsidiaries)