Activity Highlights

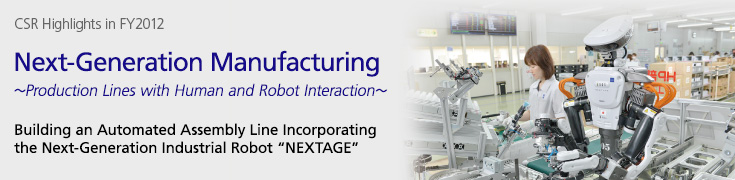

NEXTAGE-based automated assembly line

Japanese manufacturing currently faces pressing issues such as how to prevent the hollowing out of the industrial base caused by the relocation of production overseas due to factors such as the rapidly rising yen and shrinkage of working population because of the falling birth rate, and achieve internationally competitive manufacturing.

GLORY has been exploring new forms of manufacturing to find solutions to such issues, leading to our building of an automated assembly line incorporating the multi-purpose humanoid robot "NEXTAGE," which was developed by KAWADA INDUSTRIES, INC.

NEXTAGE robot stripping double-sided tape release paper

Capable of handling flexible items like rubber belts

Received "Special Award for Next-Generation Industry" at the 5th Robot Awards

Commendation Plaque

Certificate of

"Special Award for

Next-Generation Industry"

Trials of NEXTAGE were launched in November 2010, and work began on control software, but the level of complexity was greater than that of existing industrial robots. To deal with this, KAWADA INDUSTRIES dispatched engineers dedicated to NEXTAGE, while our company produced specialized attachments and parts supply equipment for the robot. The robot technology skills of KAWADA INDUSTRIES and the production technology know-how of GLORY were combined, and after much trial and error we constructed the NEXTAGE-based automated assembly line.

This success resulted in much praise for our construction of a next-generation production line on which humans and robots interact, based on the groundbreaking concept of tasking robots with the work exactly in the same manner as done by humans. For our efforts, together with KAWADA INDUSTRIES, we received the "Special Award for Next-Generation Industry" at the 5th Robot Awards (sponsored by the Ministry of Economy, Trade and Industry and the Japan Machinery Federation).