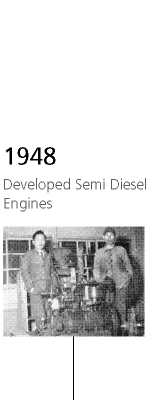

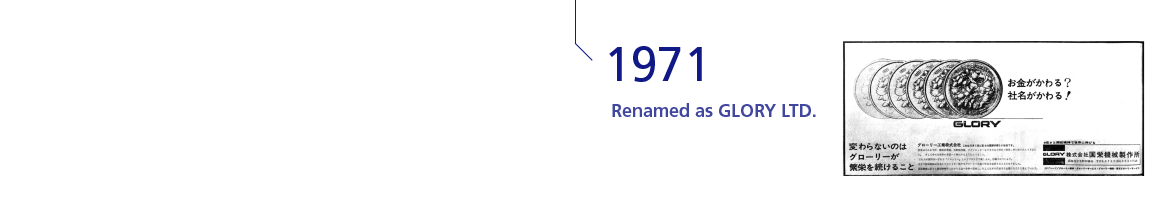

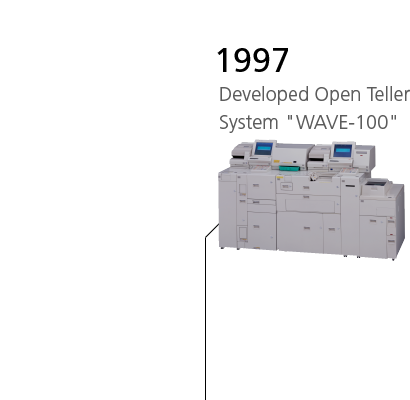

Always creating something new

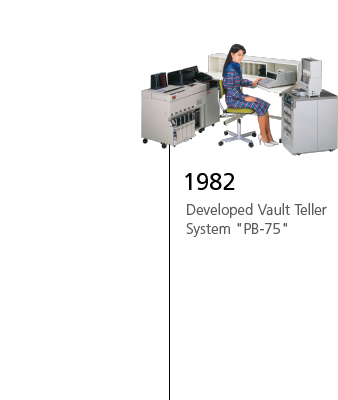

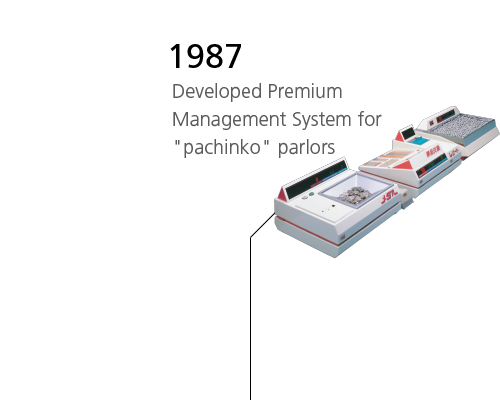

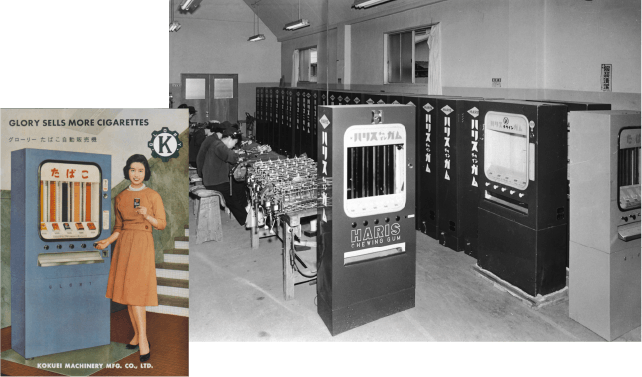

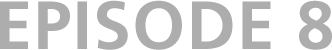

Starting with the nation’s first coin counter, we have constantly developed new

products/services by challenging the status quo.

The strong passion passed down through the generations remains rooted in the

background.

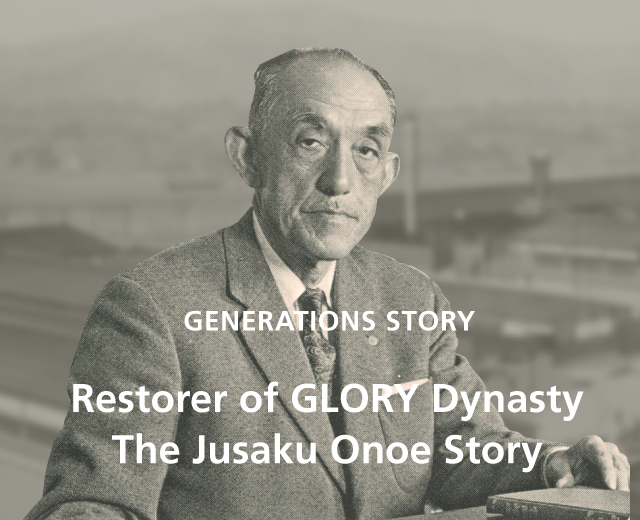

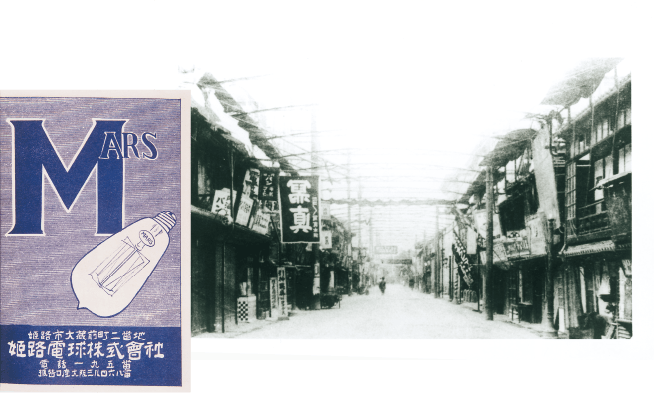

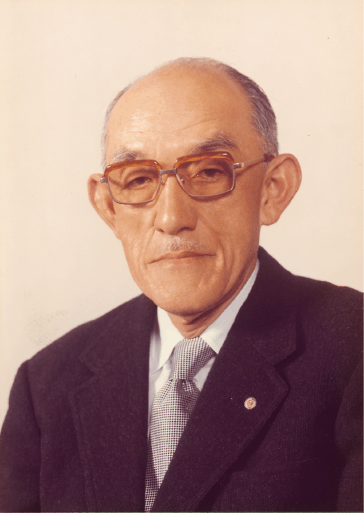

Security, Throughout the World

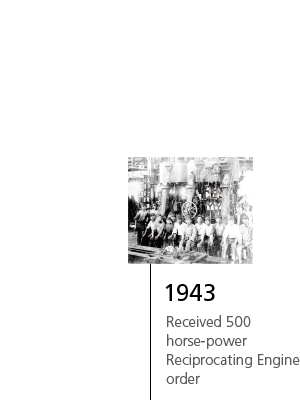

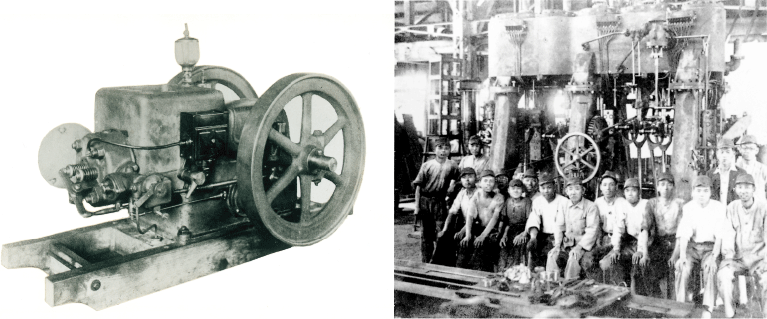

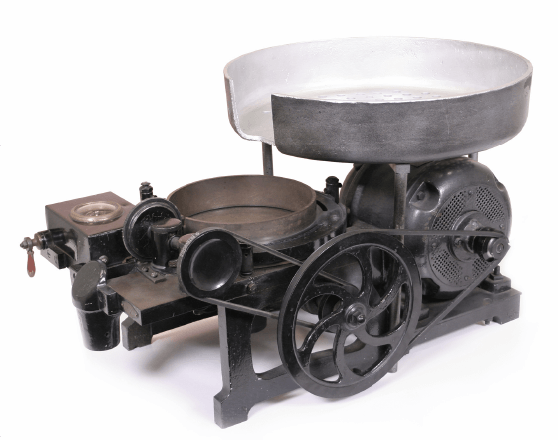

The business started as a factory for repairing and manufacturing light-bulb devices. One hundred years later, it has grown into a global company with operations in more than 100 countries around the world.